bhylene micro flow sensor

email: porter@microflowmeter.com Shanghai JSNMicro Flow Meter CO.,LTD.is a family company and it has more than 30 yearshistory. We are specialized in research of high quality flow meters, such as mircoflow meter,oval gear flow meter ,coriolis mass flow meter,electromagnetic flowmeter,piston flow meter, spur gear flow meter,gear pump,gear metering pump andso on. We devote ourselves to break the technology monopoly of foreigncountries. Our micro flow meter can replace Kracht, OVAL, SIKA and OMAGEforeign brands and so on. We have export our flow meters into more than 100countries and Shanghai JSN Micro Flow Meter CO.,LTD has already been a famous Automationinstrumentation company.

bhylene micro flow sensor

Onceupon a time, China"s manufacturing industry in the world"s processing plant hasalways been the "low quality" representative of the world. Inparticular, the Oval gear flow meter for automatic process control has theadvantages of large volume, large noise, small turndown ratio, , The use ofeasy to leak, instability and so on, leaving customers a headache is that manyproblems in the early stages of product does not appear, and in the event ofafter-sale is very troublesome, bothering money, these are domestic objectiveobjective existence of Oval gear flow meter Therefore, users buy Oval gear flowmeter is like buying lottery tickets, do not know sent to the installation siteOval gear flow meter is a blessing, in a sense, is a matter of course, whilethe base depth meter appeared to solve these problems in one fell swoop.

TheCX-M and G-series mirco flow meters are the world"s new volumetric flowmetersintroduced by BASF in 2011. Since its establishment, the CX-M oval gear flowmeter and the G-series mirco flow meters have been selling well in the marketfor more than 100,000 units a year since they were sold. The third generationlaunched in 2017, with more than 90% accuracy and stability, won thecertification of the National Bureau of Metrology. The quality and reliabilityof Shanghai JiShen instruments need not worry. According to the statistics ofChina Instrument Association, Deep flow meter reliability has always beenranked in the top 3, especially in the long-term statistics failure rate is farbelow the industry average, deep advocate "the best after-sales service isno service", but also achieved a continuous three years without qualitycomplaints .

bhylene micro flow sensor

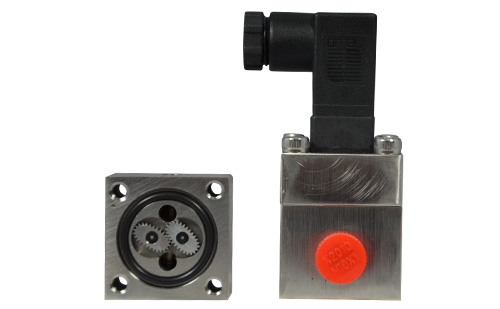

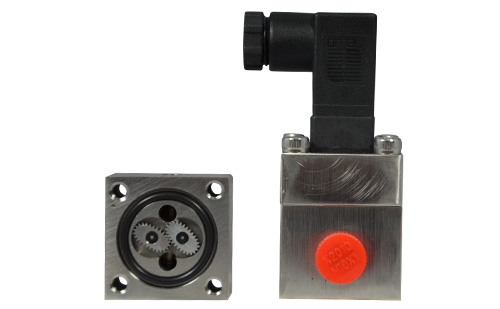

The Ovalgear flow meter is a volumetric flow meter that consists of a flow chamber in achamber and one or several elements that are rotated by fluid flow to form aflow meter. Leakage between the rotating element and the inner wall and theselected working range The internal flow rate is negligible. The rotation ofthe element is transmitted mechanically or by other means to the indicatingdevice to indicate the volume flow of the fluid flowing through.

bhylene micro flow sensor

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

What are the precautions for the gear flow meter?

1) When the flow exceeds the specified maximum flow rate, the Oval gear flow meter wear increases with the increase of the rotation speed, and the pressure loss increases sharply, should be avoided. Less than the minimum flow, although still able to measure, but the error increases. Flow meter The starting flow is about 2% of the maximum flow, and the normal working flow is preferably 70%-80% of the maximum flow.

2) Deep-rooted flowmeter is used with various viscosity media from 0.3 ~ 100000cps, different viscosity media will affect the range, the following single must be noted

3) The measured liquid temperature should not exceed the specified value, otherwise, the instrument can not work properly, or even stuck, the counter part is easily damaged at high temperatures. Liquid temperature changes will also cause additional errors in viscosity.